One of the primary ways the Tesla Model 3 distinguishes itself from its competitors, such as the BMW i3 and Chevy Bolt, is the superior handling performance. It shows that even though Tesla is competing on a similar pricing level, they are willing to spend a significant amount more on the suspension on the vehicle to impress their customers.

Background: Every OEM spends its money differently on systems throughout the vehicle. Some spend more on interior trim or seats or NVH control. In the Model 3, Tesla spends its extra money on the suspension.

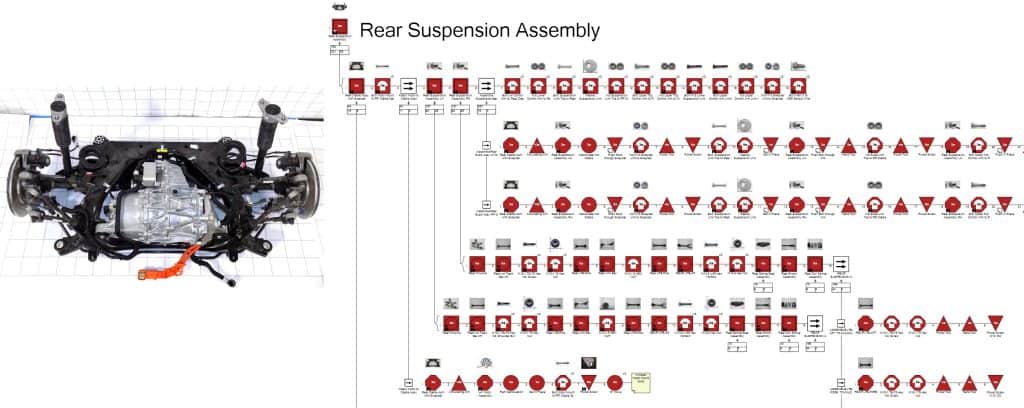

Data: The Tesla Model 3 spends $924 on its suspension versus the BMW i3 at $731 and Chevy Bolt at $642. Part of the cost in the suspension is due to the heavier weight of the Model 3, but the main difference is in the design of the rear suspension. The Chevy Bolt offers the simplest rear suspension with a fixed twist beam structure. Both the Model 3 and i3 have five link suspensions, but the i3 mounts the linkages to support structures on the frame, while the Model 3 has a full cradle with a stabilizer bar.

Methodology: The Munro team removed the front and rear suspension modules from each of the vehicles, and mapped the final assembly time and cost using Munro’s Design Profit® software. The modules were then torn down so the assembly process time and cost could be calculated. Lastly, each part was analyzed to determine the fabrication steps involved to create the parts for the suspension, all of which was documented in Design profit.