We get a lot of interest from different start up or R&D houses about how to bring new technologies into the market place and Munro & Associates is well known among its clients for bringing innovative technologies and ideas into new designs, but there is a fine line between interesting and profitable/commercially saleable.

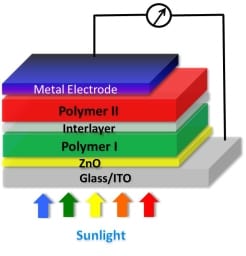

For instance, UCLA announced a 10.6 percent efficient (a new world record for polymer cells as recognized by NREL) from their new tandem organic polymer solar cells after adding a new infrared-absorbing polymer layer from Sumitomo Chemical to the research group’s already 8.6 percent efficient cells. The idea is that the new solar cells are a combined layer approach, stacking together to cover sensitivity to different absorption bands thereby capturing a wider spectrum than single-junction solar cells and thereby harvesting more energy. The trick however, is not to just add two solar cells together, you need to couple with compatible materials – in this case a specific low-band-gap–conjugated polymer for the solar cell structure.

For instance, UCLA announced a 10.6 percent efficient (a new world record for polymer cells as recognized by NREL) from their new tandem organic polymer solar cells after adding a new infrared-absorbing polymer layer from Sumitomo Chemical to the research group’s already 8.6 percent efficient cells. The idea is that the new solar cells are a combined layer approach, stacking together to cover sensitivity to different absorption bands thereby capturing a wider spectrum than single-junction solar cells and thereby harvesting more energy. The trick however, is not to just add two solar cells together, you need to couple with compatible materials – in this case a specific low-band-gap–conjugated polymer for the solar cell structure.

“Envision a double-decker bus. The bus can carry a certain number of passengers on one deck, but if you were to add a second deck, you could hold many more people for the same amount of space. That’s what we’ve done here with the tandem polymer solar cell.” said Yang Yang, a professor of materials science and engineering at UCLA Engineering and principal investigator on the research. “Everything is done by a very low-cost wet-coating process,” and “the process is compatible with current manufacturing,”

Professor Yang Yang is confident that 15% efficiency will be reached in the next few years.

UCLA is not the only kicker at this cat, a €14.2 million European research project under the European Commission’s Seventh Framework Program (FP7) is also working to develop more efficient, flexible, plastic solar panels.

There are just 2 problems:

“These things are unstable in air and water,” says Keith Emery, who manages NREL’s cell and module performance characterization group. It appears that although a breakthrough, the cells still fall short of something that can withstand the elements. This is probably not something that could survive on a double decker bus at the moment.

The next problem, of course comes in the form of competitiveness in the market place, competing with market changers such as Solar Junction who boasts 43.5% efficiency (a commercial world record set last April) and Semprius which now has a 33.9% efficient CPV cell both using multi-junction solar cell architecture. Not to mention, there is the ever decreasing cost to set up these more established higher efficiency technologies vs. higher set up, lower life span or organic polymer technologies. When you calculate the cost of purchasing, set up and maintenance of a commercial giant like Solar Junction at 43.5% efficiency vs. that of an organic polymer cell at 10% efficiency, you would have to pay the customer to buy polymer cells to be profitable. “It’s one thing to make them harvest energy and conduct electricity, but it’s another thing to make them stable and then another to figure out how to package them into a commercial-scale alternative,” says Keith.

New technology is always alluring and R&D is always an important expense of innovation, but companies and individuals always need to be wary of decisions that “make sense” versus ones that make “cents”.